Autonomous robots that independently inspect, wait and repair offshore systems under water using artificial intelligence-a vision that is currently tangible.

In order to ensure the safety of offshore infrastructures such as wind turbines or oil and gas production systems, regular inspection and maintenance is essential.However, the work under water is not only complex and expensive, but also cause considerable risks for the diving that they carry out.That is why there are already remote-controlled mini submarines to monitor the condition of maritime systems.However, the trend towards autonomous underwater vehicles (AUVs), which remain in the water over long periods of time, operate independently using methods of artificial intelligence (AI) and can also be remotely controlled if necessary.

Research consortium under the direction of the DFKI

An important step in this direction has been successful in a consortium of leading companies and research institutions from the areas of IT, robotics, drive technology and offshore under the direction of the Robotics Innovation Center at the German Research Center for Artificial Intelligence (DFKI) in the "Mare-IT" project.At the end of the project, the partners, including the DFKI research areas of cognitive assistance systems and embedded intelligence as well as Wittenstein Cyber Motor GmbH, SAP SE and Rosen Technology and Research Center GmbH, also presented a holistic solution.

Robot with two arms

This solution includes a new two-arm auvian that can be used thanks to two integrated manipulators for maintenance work and repairs to underwater structures.In addition, the partners provide a powerful IT infrastructure that not only enables intuitive control and monitoring of the robot under water.It also guarantees the smooth, bidirectional flow of information with the plant operators and allows the integration into existing business processes.

The DFKI Robotics Innovation Center has successfully designed and built up and built up in Mare-IT "Cuttlefish" as an intervention AUV that can be positioned free in the water column.The innovative AUV has two gripping systems that are attached to the abdomen side, with which it can manipulate objects under water.Thanks to its special design as well as the AI-based control and regulation.

Glass fiber enables manual control

In addition to fully autonomous use, the vehicle can be operated in a hybrid mode using a fiber fiber that allows intervention by humans, for example in critical operations on underwater structures.For this, the AUV is equipped with a variety of sensors for environmental perception, z.B.Sonar sensors, cameras, laser scanners and magnetometers. Um die große Menge an Sensordaten effektiv verarbeiten zu können, erarbeiteten die Forschenden ein spezielles Architekturkonzept, dass die dezentrale Analyse von Datenströmen direkt anBord des Roboters ermöglicht. Auch die Umsetzung der Missionsplanung zur Durchführung von Inspektions- oder Wartungsaufträgen verantworteten dieBremer Forschenden.In addition, they developed a uniform interface that enables the bidirectional data exchange between AUV, control center and the internal business internal.

Bedienpersonal trägtVR-Brille

A virtual co-pilot developed on the DFKI research area of cognitive assistance systems supports the human staff in the control center with teleoperation tasks to be carried out.For this it is equipped with a Microsoft Hololens that either in combination with the control center or as a lightweight separate interaction medium, Z.B. anBord eines Schiffs, eingesetzt werden kann.Thanks to a holographic 3D presentation on the display, the operating person is informed at any time about the current state of the AUV and the underwater structure.Sensor information and measured values can be displayed by natural language interaction and warnings can be configured.In addition, the AUV and its cameras can be controlled via voice commands and, in combination with eye tracking, information about elements of the infrastructure that the person is looking at.It is possible to define your own language terms during the mission and as an alias, z.B.to use for camera or docking positions.

Artificial magnetic fields help with localization

As a supplement to the innovative interaction technologies, the DFKI research area has developed a web application embedded in Mare-IT that allows the AUV to be controlled via mobile devices such as smartphones or tablets and make parameter settings.In addition, the researchers examined the possible uses of artificial, oscillating magnetic fields for the localization of the underwater robot.

Thruster drives create a thrust of 500 N

Wittenstein Cyber Motor GmbH developed and produced the high-robust thruster drives for the transport of the AUV.These have a thrust of up to 500 N, are protected against sea water and are suitable for water depths up to 6000 m.Bei der Herstellung, bei der spezielleVergusstechnologien zum Einsatz kamen, wurde auf dieVerwendung flüssiger Füllstoffe verzichtet, um chemische Gefahren für die Umwelt abzuwenden.The servo converters belonging to the drives include a sensorless regulation specially tailored to the thruster engine, which enables a precise, highly dynamic speed control over the entire speed range up to the standstill in both rotations. Das AUV ist mit acht derartigen Thruster-Antrieben ausgestattet, die im Gesamtverbund hochpräziseBewegungen ermöglichen, wie sie für das Andocken an Unterwasserstrukturen erforderlich sind.The real -time communication required for this takes place within the AUV using Ethernet/IP.

Administrative shell reduces integration costs

SAP untersuchte in Mare-IT, in welcher Form und unter welchenBedingungen autonome Systeme wie AUVs in IT-Infrastrukturen wie Cloud-Systeme eingebunden werden können.For this purpose, a manufacturer -independent integration of digital twins in business applications by forming the administrative shell, a central component of the Industry 4 reference architecture.0, realized.The administrative shell ensures the interoperability via solutions of any manufacturer.It reduces integration costs and expenses, especially if several organizations are to access data of digital twins.SAP shaped the administrative shell prototypically for planned and unplanned maintenance processes, for example for the insulation valve of an underwater structure.The Cloud application SAP Intelligent Asset Management can now initiate such a maintenance via the administrative shell of the insulation valve and recover the execution status by the underwater robot.Thanks to the administrative shell, any other systems of other parties can be added or replaced by others without much integration effort.

AnBord sind vier Messtechnologien

The Rosen Group, the globally leading provider of integrity management solutions for the large-scale industrial plants of the energy industry, developed four different measurement technologies for AUVs in the project to check the state of various Sensestructures: magnetic field sensors for detecting ferromagnetic structures, sensors for measuring electrical fields of cathode protection systems as well as ultrasound and ultrasound and ultrasoundSeluine current sensors for measuring local wall thicknesses using the manipulators on the AUV.In addition, a communication buoy was developed that ensures data transmission from the robot through the water column to the central control center. Rosen hat erfolgreich alle vier Messtechnologien für den Einsatz am AUV fertiggestellt und liefert somit einen wichtigenBeitrag für autonome Unterwasseranwendungen von komplexen Sensorsystemen.

The AUV upright in the water column with extended manipulators.Photo: DFKI, Thomas Frank

The AUV carries out manipulation tasks on an underwater mockup in an upright position.Photo: DFKI, Thomas Frank

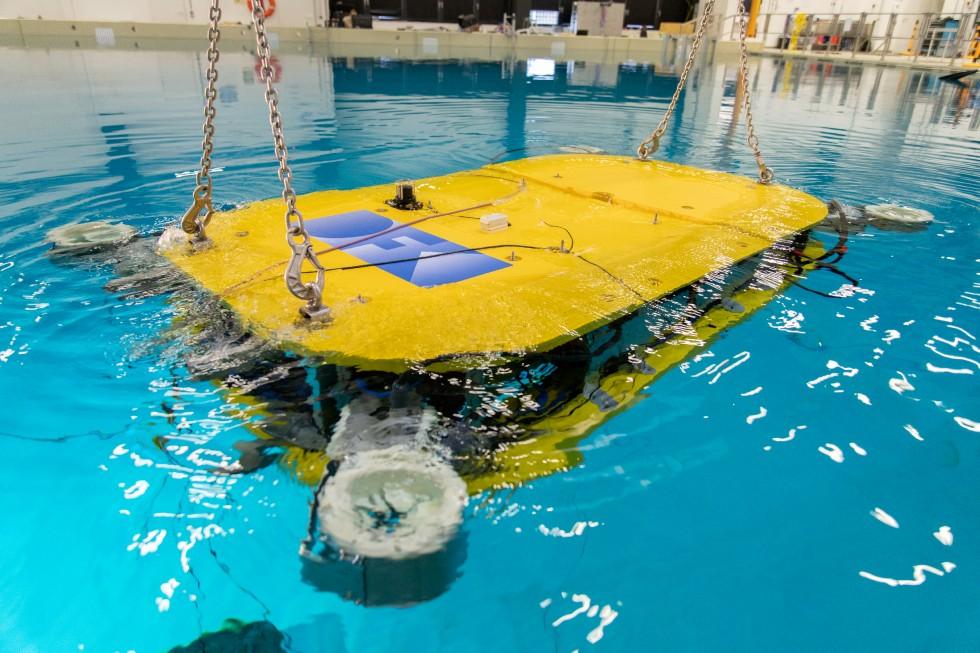

The AUV in the driving position with folded manipulators.Photo: DFKI, Thomas Frank

Ein Forscher überwacht die Kollisionsvermeidung des AUVs im Dual-Armbetrieb vomBeckenrand aus.Photo: DFKI, Thomas Frank

The MARE-IT project was from 1.August 2018 to 30.November 2021 from the project sponsor software systems and knowledge technologies of the German Aerospace Center E.V. (DLR) mit Mitteln desBundesministeriums fürBildung und Forschung mit rund 5,5 Mio.Euro funded.

Tips to do your electrical installa...

Companies in the Pinneberg district...

Maintal is becoming a smart city th...

New subway workshop and wash bay in...