At the Vienna University of Technology, a calculation model for micromechanical sensors that measure the properties of liquids or gases was developed.The new type is the connection of fluid dynamics and microdynamics.

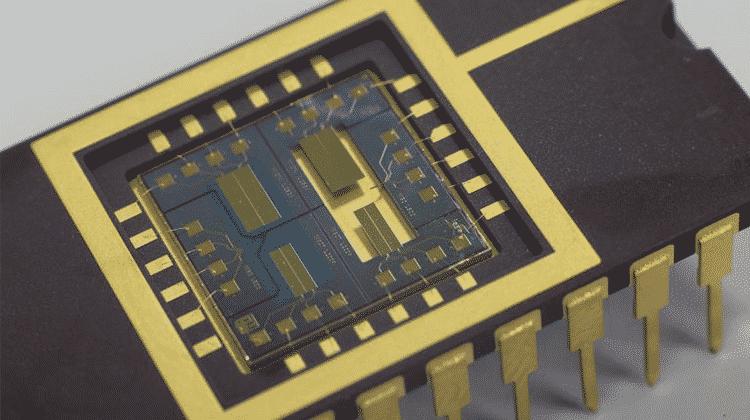

Micromechanical sensors combine two different worlds: on one side the world of electronics and digital signals, on the other hand the more physically tangible world of mechanics.The connection between these areas is often not easy, and so far a comprehensive model has been missing, with which one can describe tiny plates or beams exactly, which can be swinged by electrical effects.At the Vienna University of Technology, it was now possible to develop such a model - in excellent agreement with measurement results.This now enables tiny sensors that can be used to measure the properties of liquids or gases precisely and simply.

Characterize liquids with swinging micro-plates

The vibration behavior of the microstructures depends very much on two factors: firstly on their geometry and secondly from their surroundings: if the microstructure is in a tough liquid, then the vibration is steamed and the vibration frequency changes.

"In this way you can detect changes in the environment very quickly," explains Ulrich Schmid."For example, through a microelectromechanical sensor, you could monitor in an oil container whether the oil still has the right viscosity or whether it has changed its properties through aging and has to be replaced."

However, if you want to calculate the vibration behavior of these tiny structures, you come across a number of difficulties: there are arithmetic models to describe the vibration of small beams or panels, but this vibration must be mathematically with the behavior of the surrounding liquid or the surrounding gasto be coupled - you have to connect vibration mechanics and fluid dynamics.

„Das ist numerisch aufwändig, auch deshalb, weil man es hier mit unterschiedlichen Größenskalen zu tun hat", sagt André Gesing."The diameter of the swinging structures lies in the milli to micrometer range, but the amplitude of the vibrations in the nanometer range.This difference of more than three orders is the reason that conventional finite element methods, as you use in many other research areas for the analysis of vibrations, quickly reach their limits here."

New model: versatile and precise

Nun ist es AndréSinging, Daniel Platz und Ulrich Schmid vom Institut für Sensor- und Aktuatorsysteme der TU Wien gelungen, eine Methode zu entwickeln, die all diese Schwierigkeiten meistert, und noch dazu viel umfassender ist als bisherige Modelle: „Damit kann man Mikrostrukturen unterschiedlicher Form und Größe analysieren, mit unterschiedlich starken Dämpfungen", sagt Daniel Platz.So you can now predict which structures are most promising for which application.Experiments show that the new arithmetic model is very suitable with the measured data.

This findings are important not only for the production of sensors, but also for the scanning force microscopy: there the vibration of extremely fine needles is measured in order to obtain information about a surface that is to be mapped point by point.The new model should now also help to develop new sensors for raster force microscopy, especially for the examination of biological samples in liquids.Another field of application is the forward -looking maintenance (predictive maintenance) of hydraulic components.Microsensors can be integrated directly into such components and thus continuously deliver data on oil quality.In this way, system failures can be prevented at an early stage and minimize the maintenance -related service life.

„Diese grundlegenden Erkenntnisse, die wir nun gewonnen haben, sind die Basis für die weiteren Ziele, die wir nun verfolgen: Wir wollen nun mikromechanische Sensoren verbessern und ihr Anwendungspotenzial vergrößern", sagt Daniel Platz.It will not only be about the interaction between the structure and the surrounding fluids, but also about the question of how other energy loss mechanisms can be reduced to a minimum. „Auf Basis dieser Untersuchungen wollen wir mikromechanische Sensoren mit sehr hohen Gütefaktoren entwickeln, wie sie zum Beispiel in der Quantensensorik verwendet werden", sagt Daniel Platz.

Original publication.Singing, D.Place, u. Schmid, A numerical method to determine the displacement spectrum of micro-plates in viscous fluids, Computers&Structures, 260, 106716 (2022).

Tips to do your electrical installa...

Companies in the Pinneberg district...

Maintal is becoming a smart city th...

New subway workshop and wash bay in...