This is the first part of a new tutorial column on airliners.de, which shows the structure and actions of aviation companies. The "Aviation Technology Management" series is aimed at employees at officially recognized companies that develop, manufacture or maintain aeronautical products. It is explained how these operations must be structured in terms of structure and processes in order to meet the requirements of the European Aviation Safety Authority (EASA).

In this first part, the organizations and authorities that monitor the legal framework for aeronautical companies and, in some cases, set them themselves, are introduced. With their actions, these institutions largely determine the basic structure and the general functioning of aeronautical companies. The EASA regulations are explained in a second section, because knowledge of these requirements is an important prerequisite for an overall understanding of the structural and process organization of companies in the aviation industry.

European Aviation Safety Agency (EASA)

The European Aviation Safety Agency (EASA) is the aviation regulatory authority of the European Union. EASA was founded in 2002 to ensure a uniform EU-wide level of safety and environmental protection in civil aviation. EASA currently has 31 member states. In addition to the EU nations, Switzerland, Lichtenstein, Norway and Iceland are also part of the EASA area. The agency's office is in Cologne. In detail, the tasks of EASA with its approximately 800 employees in the field of industrial aviation management are:

Luftfahrt-Bundesamt (LBA)

The German Luftfahrt-Bundesamt (LBA) was founded in 1954 and is the federal authority responsible for civil aviation tasks in Germany. It is subject to the supervision of the Federal Ministry of Transport and Digital Infrastructure. The office of the LBA is Braunschweig. In addition, the LBA maintains branch offices in Berlin, Düsseldorf, Frankfurt/Main, Hamburg, Munich and Stuttgart as well as the administrative office for air traffic control in Langen in southern Hesse.

Interesting entries from the airliners.de company finderch-aviation GmbH

Knowing is better than wondering.

To the company profile

TEMPTON Personaldienstleistungen GmbH

Aviation department

To the company profile

STI Security Training International GmbH

We train your security.

To the company profile

Worms University

Knowing what is important!

To the company profile

Flight Consulting Group

Dispatch, Trip Support and Ground Handling

To the company profile

Flughafen Memmingen GmbH

Bavaria's third largest commercial airport

To the company profile

TRAINICO GmbH

Competence & Passion for aviation

To the company profile

IU International University of Applied Sciences

WE ARE IU!

To the company profile

Lufthansa Technical Training GmbH

By experts - for experts

To the company profile

All company entriesCreate a company entryThe main tasks of the authority in the field of industrial aviation management include:

International Civil Aviation Organization (ICAO)

The International Civil Aviation Organization (ICAO), founded in 1944, is the sub-organization of the United Nations (UN) responsible for civil aviation. Its core task is standardization and regulation in the field of civil aviation, with the aim of ensuring safe and efficient air traffic. The ICAO creates basic rules in all fields of civil aviation. This is for example

Federal Aviation Administration (FAA)

The Federal Aviation Administration (FAA) is the US aviation regulatory authority and thus the US equivalent of EASA or the LBA. In this respect, their tasks are comparable. The FAA is mentioned here because its decisions often have a direct influence on the European aviation industry. Conversely, EASA also influences developments in the US aviation industry. The reason for the mutual dependency is their close interlocking, caused by a lively exchange of goods and services.

In the aeronautical engineering management column, Prof. Martin Hinsch explains how aeronautical engineering companies are structured. The text is closely based on his reference book "Industrial Aviation Management - Technology and Organization of Aviation Operations", which will be published in the spring of 2019 in a new, 4th edition by SpringerVieweg Verlag.

Structure of the EASA set of rules

EASA has issued rules that steer the development, manufacture, maintenance and operation of aeronautical products within their area of responsibility in a uniform and safe manner. Compliance with these requirements must be ensured by all companies that are active in the respective area.

The EASA regulations, which are important for industrial aviation companies, essentially consist of three regulations. These provisions have the character of law.

The EASA set of rules has a multi-level structure and distinguishes between a basic regulation and two subordinate implementing rules. The Basic Regulation defines the structure of the actual set of rules in the form of the scope, the goals and terms. The implementation regulations go further and give the authorities and aviation companies direct specifications with regard to the requirements and procedures of the respective technical field. The most important operational regulations are the

In the further course, the focus is on the IR Initial Airworthiness with Part 21 and the IR Continuing Airworthiness with Part 145 and Part-M. The operating modes relevant here are described in these two parts:

The EASA set of rules is supplemented by interpretation material which – unlike the Implementing Rules – is not published by the EU but by EASA. It is not formally binding, but only recommended. With close orientation to the GM and the AMC, however, the companies have certainty that their actions are in accordance with the regulations. A distinction is made here between the Guidance Material (GM) and the Acceptable Means of Compliance (AMC).

The EASA regulations listed below each have similar requirements for the approvals. Roughly speaking, it is always about operational QM structures in the areas

EASA Part 21J - Design organizations

Design organizations within the meaning of EASA Part 21J are all organizations that develop aeronautical products, parts or equipment or define modifications or repair processes for them. In order to be approved as an officially recognized design organization, the organizations must have demonstrated their qualifications. 21J companies can be imagined as virtual organizations within companies. The requirements for these so-called design organizations are specified in the Implementing Rule Initial Airworthiness EASA Part 21 Subpart J (Part 21/J for short). Supplementary implementation advice is given by associated AMC and the corresponding guidance material. Official supervision of design organizations is carried out by EASA.

As a usable result, development companies create approved manufacturing, maintenance or repair specifications (approved data). In order to release this documentation, 21J companies must carry out the following activities:

On the basis of these activities, EASA issues certificates of airworthiness (type certificates) and approvals for components and equipment after examination. In addition, EASA approves repair procedures.

In design and construction, statutory building codes are developments at a technical level. They thus specify the future quality of products and at the same time specify how airworthiness is to be demonstrated for them (e.g. through tests or calculations). EASA building regulations are referred to as Certification Specification (CS).

EASA Part 21/G - Manufacturing

Aeronautical manufacturing includes all activities that are directly related to the manufacture of aircraft, engines and parts and equipment. Only officially recognized companies are allowed to manufacture aeronautical products.

The requirements for these so-called manufacturing companies are defined by the EASA through the Implementing Rule Initial Airworthiness in Part 21 Subpart G (abbreviated: Part 21G). Similar to Subpart J, there is also supplementary interpretation material (AMC or Guidance Material) for the production. In contrast to design organizations, operational responsibility for production organizations does not lie with EASA, but with the national aviation authorities, i.e. the LBA in Germany.

In order to produce the scope applied for, the company must have demonstrated its qualification and a QM system. Only then does the Luftfahrt-Bundesamt issue a manufacturing license according to Part 21G in a scope usually defined at component level.

Production within the meaning of Part 21G may then only take place on the basis of approved manufacturing specifications (Approved Design Data) from an officially approved Part 21J development organization. Manufacturing companies are therefore not permitted to construct and subsequently manufacture aeronautical products "on their own initiative". In principle, a manufacturing company may not carry out any maintenance on its own components. This requires an additional approval as a maintenance organization in accordance with EASA Part 145.

EASA Part 145 - Maintenance

Maintenance organizations within the meaning of EASA are all organizations that maintain aeronautical products, parts or equipment according to approved documentation. The activities can be overhaul, replacement, repair, inspection or changes (modifications) to aircraft, engines and components.

The requirements for maintenance companies (maintenance organizations) are defined by EASA through the Implementing Rule Continuing Airworthiness in Part 145. A similarity with the EASA Part 21/G for production companies can be seen in large parts, although the EASA Part 145 has a significantly higher level of detail.

Even maintenance organizations may only carry out all activities within the officially approved scope of approval (ratings). These are pronounced individually at the aircraft/engine type level or in relation to specific components. Such ratings are set not only for the companies, but also individually for the mechanics.

Maintenance may also only be carried out on the basis of approved maintenance specifications (Approved Maintenance Data) from an approved 21J design organisation. The most common maintenance specifications are, for example, the Aircraft and Component Maintenance Manuals (AMM or CMM), the Engine Manual (EM) or the Structure Repair Manual (SRM). This documentation describes the type, scope and execution of the maintenance measures.

EASA Part-M - Continuing airworthiness

The EASA Part-M of the Implementing Rule Continuing Airworthiness defines which requirements the operator of an aircraft has to meet for sustainable continuing airworthiness . Part-M regulates maintenance management, i.e. when, which aircraft components are to be maintained and, if necessary, continuously monitored. The tasks of this maintenance management are described in the third part of our series.

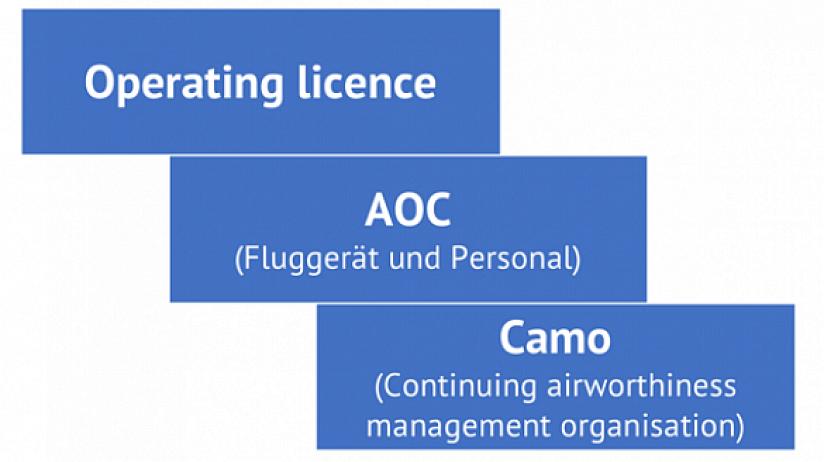

The Part-M thus forms the interface between the operator of an aircraft and the maintenance organization. The maintenance of airworthiness must be controlled and monitored by a separate form of operation approved under aviation law, the Continuing Airworthiness Management Organization (CAMO).

The aviation technology management tutorial will be published once a month from now on. The next episode will be out on February 13th. This is about the model approval process.

About the author

As an expert in aeronautical engineering, Prof. Martin Hinsch explains in his tutorial column "Aviation Engineering Management" on airliners.de how aeronautical engineering companies are structured and how they work.

Prof. Dr. Martin Hinsch is an expert in aviation quality, safety and process management and teaches business administration with a focus on aviation management at the IUBH in Hamburg. He is also approved as an authenticated aviation auditor. Through his management consultancy (aeroimpulse.de) he supports aeronautical industrial companies in development, production and maintenance. Before his current job, he worked for around ten years at Lufthansa Technik AG and as a senior consultant in Qatar.

Companies in the Pinneberg district...

Tips to do your electrical installa...

Maintal is becoming a smart city th...

New subway workshop and wash bay in...